Top 8 Subterranean Sites We’ve Surveyed

29 September 2025 by: Macleod Simmonds

From discovering what’s underneath our airports to detailed utilities mapping, we’ve been invited to carry out specialist geospatial surveys on some landmark projects. Here are eight of our favourites.

1. Saving Aylesford Reservoir

This reservoir in Kent supplied clean water to Maidstone Hospital and 6,000 homes before it was discovered that it was collapsing and leaking millions of litres each day. As an emergency contingency plan, South-East Water had to re-route the supply to the area while a solution was sought. We were contracted to carry out a geophysical survey and, using our innovative Electrical resistivity tomography (ERT) technique, we were able to find and model the void under the reservoir. This digital model enabled critical evaluation of the site conditions and informed the design of a solution that stopped the leaks, saving time and costs throughout construction. This work led on to several similar jobs requiring both ERT and ground penetrating radar (GPR) based technologies.

2. Rapid Survey of M40 bridges

Sometimes we make complex jobs look easy. When asked to survey twenty five live bridges along the M40 corridor for variations in surface material thicknesses and potential signs of structural deterioration, we successfully completed the job in just two days. Using our Ultra-Wide Band High Density Array Ground Probing Radar (UWB HDAGPR) system, supplied by Kontur, all survey works were carried out in live traffic without the need for traffic management. This step frequency radar works in the frequency domain rather than the time domain, and can look into deep as well as thin materials. The system is positioned in real time using a Total Station or RTK GPS and is mounted on a van. Simply by driving back and forth across each bridge, the full carriageway width is covered, allowing anomalies and surfacing material thicknesses to be quickly assessed.

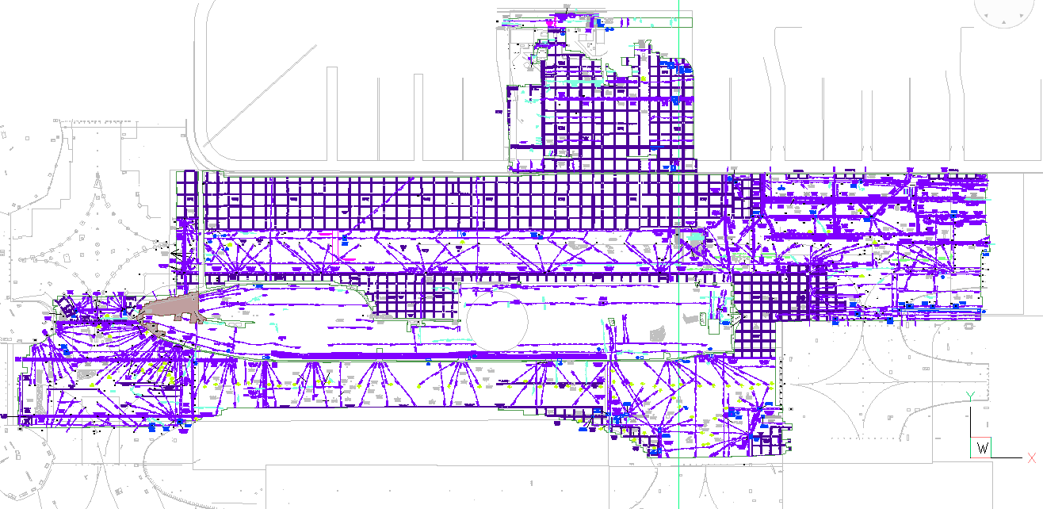

3. Revealing Heathrow and Gatwick’s buried past

Ever imagined what lies beneath the surface of our busiest airports? You’d be amazed! Our surveys reveal clear pictures of original taxiway and runway lighting systems, and all the cables connecting them, 12 inches under the ground. We can also clearly visualise the vast expanse of the utility networks present, along with the original pavement construction beneath the existing surface detail. We were commissioned to carry out multiple GPR inspection surveys at both Gatwick and Heathrow airports, prior to repair work on the busy taxiways. At both airports, down-time had to be kept to a minimum while surveying was under way and specialised airside qualified staff were needed to facilitate the project, which had to be carried out in full compliance with applicable Health and Safely and airport security regulations. Our high-density array ground penetrating radar (HDAGPR) was able to survey huge areas quickly and accurately and found subsurface objects that nobody had any record of. The detail of the images we produced was remarkable and enabled repair work to be planned with full knowledge of what they were digging into.

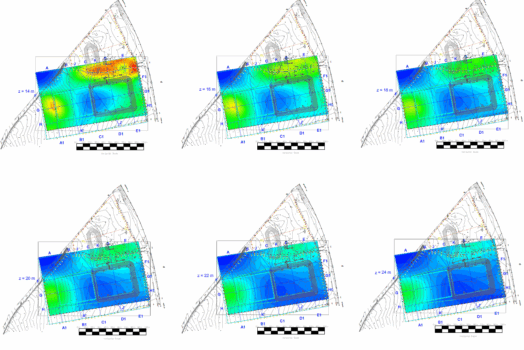

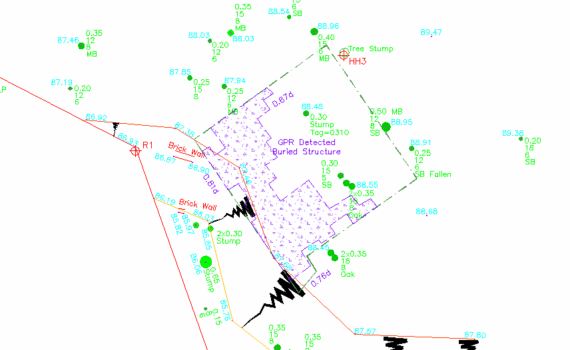

4. Unearthing a forgotten air raid shelter

For developers planning extensive excavations, a buried building is something it’s best to know about before breaking ground. Alerted to the possible existence of a structure buried in the woods near Aldershot, we set to work using a specialist ground probing radar system, to see what we could find. What emerged was an extensive concrete WWII air raid shelter, completely submerged beneath the soil. We used a pulse radar with a low frequency antenna to give us a greater depth of penetration. Although this gives a lower resolution image, it’s the best method for surveying big structures, as higher frequencies can pick up too much detail and lack the required penetration depth. Using a grid of radar measurements, we were able to create individual cross-sections, which we could then manipulate using our ‘in-house’ GPRCAD software, before exporting into CAD and plotting as a plan outline.

5. Mapping the City’s subsurface congestion

The City of London’s ‘Square Mile’ is one of the most densely populated areas in the world, and demand on utilities is ever-increasing. Subsurface congestion is so great that in some places there’s virtually no contact between surface and soil – the carriageway is literally sitting on the utilities. To help the City’s new planning strategy, we were asked to produce a large-scale assessment of this congestion. Using an Ultra-Wide Band High Density Array Ground Probing Radar (UWB HDAGPR) system, coupled with the DXG2124 antenna system, we scanned 25km of carriageways to a depth of one and a half metres in live traffic. We then manipulated the way software works with the data we’d gathered to plot congestion density on a colour-coded map. This map is now a valuable tool in planning negotiations, used regularly to inform decisions and ensure the seamless execution of future construction developments.

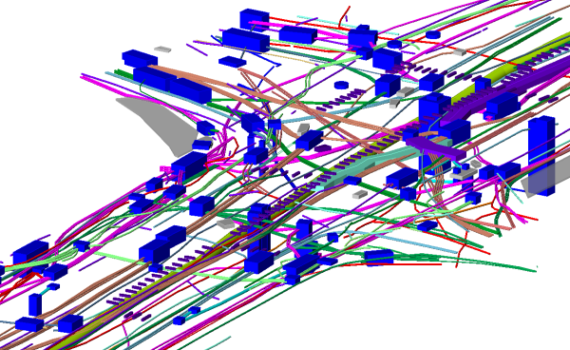

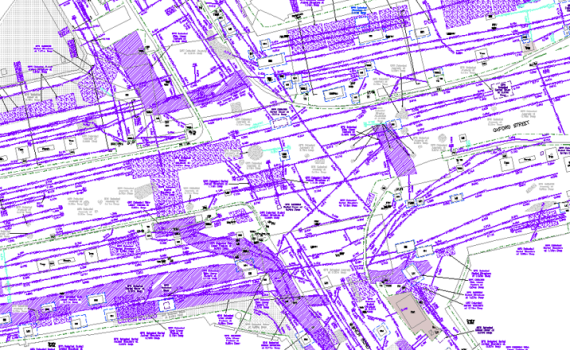

6. Looking beneath Leadenhall Street

What began as a radar only pavement inspection to produce an overview of what’s buried beneath this historic London Street, turned into something much more complicated. The plan was that the client would review our radar survey and then, depending on their designs, come back to specific areas and upgrade the survey. However, because we found so much with our first pass, they asked us to carry out a full utilities survey from Leadenhall Street up to Liverpool Street. That’s a very busy area with lots of communications cables running under the ground, and we had to carry out a lot of invasive work, including lifting every manhole cover. This type of project is extremely complicated, using our unmatched experience in this type of environment, we were able to produce a detailed map of all the utilities in the area.

7. Resurfacing Earls Court

The regeneration of London’s Earls Court includes extensive work to a number of roadways, under the jurisdiction of Transport for London. In many places the road structure has been compromised by the many utility installations and simple resurfacing would only fail again. The road contractor wanted us to create depth maps, showing the varying pavement levels and what lay beneath. This would enable them to set their planers to the optimum depth to avoid any obstacles. It also provided the scheme designers with invaluable information on the remaining structurally sound areas of construction, along with those compromised through previous excavations and reinstatements. Thus the job could be completed without punitive delays. The map we produced was colour-coded to show the position and depth of utilities, plus any voiding, poorly compacted trenches and the general state of the road. It proved invaluable in enabling them to complete their work on time, avoiding any fees for overrunning.

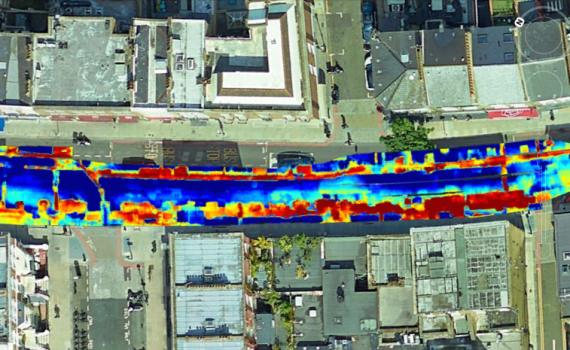

8. Oxford Street – Strategic Utility Surveys

Being involved in many of the Cycle Super Highway projects across London, it became clear that the sheer length and time required to deliver these projects was becoming a problem. We subsequently designed a new, cost-effective approach to delivering these surveys. This Oxford Street project, along with subsequent ones, gave scheme engineers precisely the information they needed, whilst cutting fees by up to 75% and enabling schemes to be delivered in weeks rather than months.

The methodology begins with whole route coverage using HDAGPR technology, then imaging the subsurface from the collected data. All detected features, utilities and structures are then incorporated into a topographical survey and presented as a scaled CAD model. Scheme engineers then review this dataset for potential design conflicts, which are further investigated through strategic cover lifting and Electro-Magnetic Locator (EML) systems. These areas are upgraded to a PAS128 equivalent level of detail, resulting in reduced stakeholder costs, accelerated project timescales, and the critical information required for the safe and efficient delivery of the scheme.

Macleod Simmonds specialises in cutting-edge geospatial surveys.

If you think any of the above services would add value to your project, please get in touch.